KENT

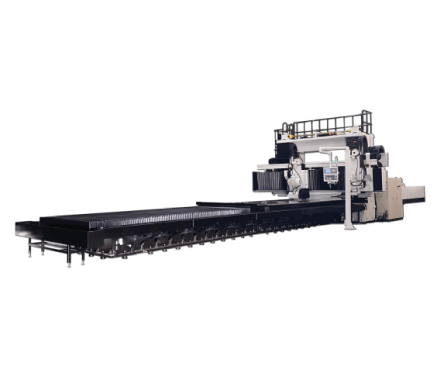

KGP-Double Column Surface Grinder

Machine Features:

- Machine mechanical structure : Machine main structure are cast of high grade FC-30 iron to ensure high rigidity and stability. Column designed in box type structure to achieve high performance and reduce resonance in heavy duty cutting.

- Control system : Graphical user interface with Mitsubishi color touchscreen deliver easy conversation operation system. Easily pre-set grinding parameters for a automatic cycle, improving working effiency. Mitsubishi PLC provides a long, trouble – free operating life. Easy maintenance supported by an extensive service center network located all over the world.

- Spindle and spindle motor : The Flange type spindle is designed with a strong shaft, supported by 3 sets super precision angular contact bearings with wide span, to maximum rigidity and machining accuracy. High torque spindle motor (20HP) adapts high technology to attain low vibration, greater rigidity, high bending resistance. It suits to demands for heavy cutting.

- Slideways : Cross and vertical axes driven by high precision C3 grade ball screws and servo motor, supported by backlash-free coupling, to ensure accurate movement. Slideways are box way to guarantee high rigidity, stability and long lasting performance.

- Hydraulic system : Advanced hydraulic system with proportional valve and 20HP motor ensures table speed up to 30 m/min. Hydraulic tank is standarly equipped with a oil chiller ito prevent heat dissipation and maintain normal temperature of hydraulic oil. All parts inside the system are corrision – proof, ensure easy maintenance and long lasting service.

- Automatic wheel dressing and compensation : The dresser is for horizontal grinding wheel, driven by DC motor and fed by servo motor. Easily pre-set the dressing parameters for an automatic cycle.

- Automatic lubrication system : Centralized automatic lubrication system with tank capacity of 100 litters can provide proper, precise lubricant replenishment to all required points at the right time.

- Vertical grinding attachment (optional) : Vertical grinding head: flexible, accurate and reliable grinding solution for cutting – edge. Easily adjust angle for various applications such as flank grinding , dovetail groove, side cutting and chamfering

Machine Specifications:

| Specifications | Unit | 1524D | 1532D | 1542D | 2032D | 2042D | 2050D | 25100B | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Table working area | mm | 1500x2400 | 1500x3200 | 1500x4200 | 2000x3200 | 2000x4200 | 2000x5000 | 2500x10000 | |

| Longitudinal travel | mm | 2500 | 3300 | 4300 | 3500 | 4500 | 5500 | 11000 | ||

| Distance between columns | mm | 2000 | 2500 | 3000 | ||||||

| Table load including magnetic chuck | kg | 6000 | 8000 | 10000 | 9000 | 12000 | 15000 | 40000 | ||

| Table | Table speed | m/min | 5 ∼25 | |||||||

| Rapid crossfeed | mm/min | 10∼2000 | 10∼1800 | |||||||

| Min.crossfeed increment | mm | 0.001 | ||||||||

| Horizontal head | Spindle center to table | mm | 1150 | 1750 | ||||||

| Elevation speed | mm/min | 2∼500 | ||||||||

| Min.downfeed increment | mm | 0.001 | ||||||||

| Wheel dimensions | mm | ∅510x100x203.2 | ∅610x100x254 | |||||||

| Spindle speed | 50HZ | r.p.m | 1000 | |||||||

| 60HZ | r.p.m | 1200 | ||||||||

| Spindle motor | hp(kw) | 20/30/40(15/22.5/30) | 40(30) | |||||||

| Cross travel | mm | 1600 | 2100 | 3300 | ||||||

| Vertical head | Spindle center to table | mm | 840 | 1750 | ||||||

| Elevation speed | mm/min | 2∼500 | ||||||||

| Min.downfeed increment | mm | 0.001 | ||||||||

| Swivel (Left / Right) | deg. | L60*/R60* | ||||||||

| Wheel dimensions | mm | ∅355x50x127 | ∅405x50x127 | |||||||

| Spindle speed | 50HZ | r.p.m | 1500 | |||||||

| 60HZ | r.p.m | 1800 | ||||||||

| Spindle motor | hp(kw) | 10/15(7.5/11) | ||||||||

| Cross travel | mm | 1600 | 2100 | 2900 | ||||||

| Dimension & weight | Net weight | kg | 31000 | 33000 | 35000 | 42000 | 45000 | 48000 | 170000 | |

| Gross weight | kg | 35000 | 37000 | 39000 | 46000 | 49000 | 52000 | 200000 | ||

| Space occupied | Single | mm | 10500x4600x4500 | 12100x4600x4500 | 14100x5375x4500 | 11500x5375x4500 | 13500x5375x4500 | 15500x5375x4500 | ||

| Double | mm | 10500x5900x4500 | 12100x5900x4500 | 14100x5900x4500 | 11500x6775x4500 | 13500x6775x4500 | 15500x6775x4500 | 24000x7630x5700 | ||