BAISON LASER

FIBER TUBE LASER CUTTING MACHINE

Machine Features:

G22 SERIES

Versatile And Professional Tube Cutting Machine

Unlimited tube tybe

Full stroke with loading or feeding or receiving rack

Imported precise components

G Series

- Laser Power: 1500W-6000W

- Tube Cutting Length: 6500mm

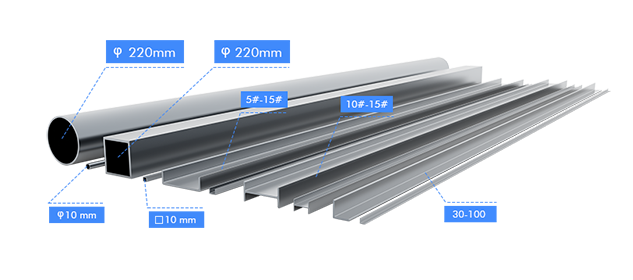

- Round Tube Diameter: φ10-220mm

- Square Tube Diameter: □10-150mm

- Capable of cutting various pipes, tubes, structural beams, open sections, profiles

- Equipped with automatic loader and unloader, high productivity and efficiency.

Dynamic Movement

Bpneumatic front chuck and solid rear chuck, full stroke external roller increases chuck clamping trust and bearing capacity. Strong clamping force and anti-skid claw makes the tubes not easy to fall off.

Strong Versatility

Except normal round pipe, square tube and rectangular, other special shapes like triangular, oval, H-beam, U-channel, open shaped structural beams can be firmly holder by the chuck without deformation.

Easy Operation

Intelligent bus real-time system and handhold box control, fast cutting and stable following of the tube corner can be achieved, ensuing reliable cutting quality.

Full Stroke Professional Pneumatic Chuck>

> Fully sealed chuck

> The rear chuck has an air blowing function, which can effectively protect the chuck from dust and dust falling into the jaws.

Optional Loading And Unloading Rack>

>Modular design for flexible use

>Improve efficiency for mass production by one-click feeding.

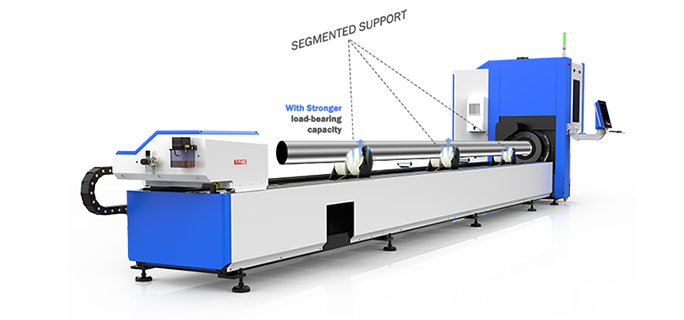

Intelligent Follow-up Support System>

> Up and down intelligent follow-up support for stronger load-bearing capacity and higher precision

> Assists the tube to turn over stably and avoid scratches.

Machine Specifications:

| Feature/Model | G22 | G22X |

|---|---|---|

| Laser Power | 1500W x 6000W | 1500W x 6000W |

| Pipe Processing Range | 10-220mm / ▯10-150mm |

10-220mm / ▯10-150mm U-Steel 5#-16# / I-Beam 10#-16# / Angle Iron 30-100 |

| Pipe Processing Length | 6500mm | 6500mm |

| Max Single Tube Loading Weight | 170kg | 205kg |

| Max.Acc.Speed | 0.8G | 1.0G |

| Max. Chuck Speed | 100r/min | 107r/min |

| Tail Length | 130mm | 130mm |

| Overall Dimensiond(LxWxH) Withhout Feeding abd Receiving Device | 9300x2700x2400mm | 9680x2700x2620mm |

| Machine Weight Without Feeding and Receiving Device | ≈2958kg | ≈4900kg |