JING DUANN

FP-XG Hot Forging Presses

Machine Features:

FP-XG Hot Forging Presses

XG type is driven by gear, can reduce travel speed through gear ratio design to achieve slow molding effect. Applicable to forging molding of aluminum, copper and other non-ferrous materials, but also suitable for needs of long extension engineering forged steel parts, such as automotive transmission shaft CV-Joint.

X-type Slider Guide Rails Slider guide rails adopt X-type design, fully overcoming the thermal expansion phenomenon caused by the heat conducted from mold to slider when forging.

The design makes sliding gap variation be reduced to a minimum, and long guide rail design enhances overall rigidity and eccentric load capacity, so more suitable for precision multi-station forging operations.

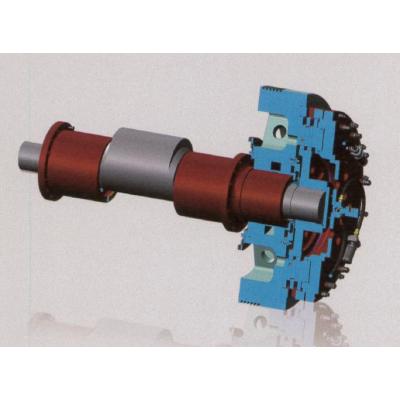

New-type Flywheel, Large Gear Suspension Mechanism

Revised flywheel and gear suspension way to improve flywheel and clutch weak points. After improvement,

- Flywheel and large gear are hung on bearing, so weight is no longer hung on eccentric shaft, and copper lining will not heat up and can reduce wear of copper lining and improve service life when rotating.

- New-type suspension design can ensure running smoothly without deflection of flywheel and large gear, greatly reducing the noise generated when gear is in operation and improving gear service life.

- Internal bearing of flywheel adopts forced machine oil lubrication, ensuring never lack of machine oil and also improving service life of bearing due to cooling effect of machine oil.

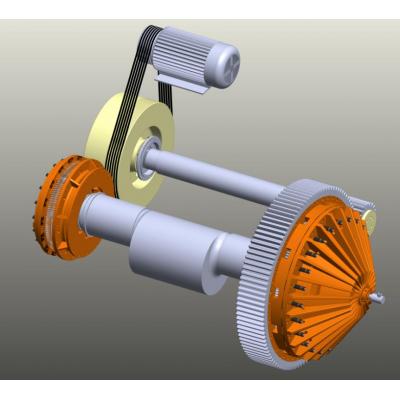

Semi-hermetic Clutch Mechanism

The semi-hermetic clutch mechanism guides external cooling air into clutch through rotary motion, increasing heat dissipation effect and effectively reducing internal operating temperature of clutch, increasing contact area of lining sheets, enhancing clutch transmission torque, and at the same time prolonging service life of lining sheets.

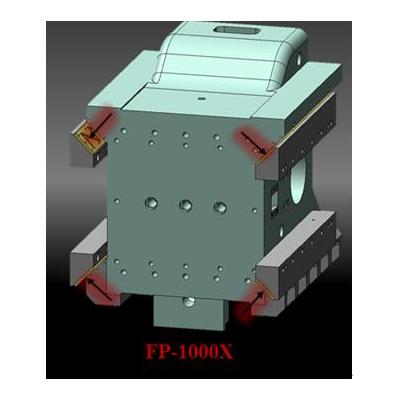

Ultra High Rigidity Machine Frame

- Strength of four steel plates on top of machine frame is strengthened to make it present an arched shape, enhancing machine frame rigidity and reducing machine frame deformation, at the same time sharing eccentric shaft load and reducing impact force on machine frame to protect eccentric shaft to avoid the occurrence of fracture.

- The structure of machine frame is optimized, enhancing machine frame rigidity and reducing internal stress load, so more suitable for heavy duty forging operations.

Machine Specifications:

| Advantages | Design | ||

|---|---|---|---|

| High Production Efficiency Longer Die Life |

FP-XG is driven by gear, can reduce travel speed through gear ratio design to achieve slow molding effect

|

||

| High Precision Forging Parts Stable Product Quality |

Slider guide rails adopt X-type design

|

||

| High Safety Standard Ensure the Safety for Operator and Machine |

HMI Touch Screen, I/O Monitoring PLC Multi Circuit Loop System, Micro Computer Load Meter |

||

|

Fulfill the Environmental Protection Standards |

New-type Flywheel, Large Gear Suspension Mechanism |

||

| Easy to MaintenanceEasy to Operate | Well Designed Lubrication System Mold Stuck Releasing System |

||

| Iron, Aluminum, Copper and Titanium Alloys are Practicable in forging |

Ultra High Rigidity Machine Frame & Semi-hermetic Clutch Mechanism

|

| Item/Model | Unit | FP-600XG | FP-800XG | FP-1000XG | FP-1300XG | FP-1600XG |

|---|---|---|---|---|---|---|

| Capacity | Tons | 600 | 800 | 1000 | 1300 | 1600 |

| Stroke of ram | mm | 200 | 250 | 250 | 280 | 300 |

| Adjustnent of ram | mm | 10 | 10 | 10 | 10 | 10 |

| Number of stroke | Spm | 70 | 60 | 60 | 60 | 50 |

| Work number of stroke | Spm | 18 | 18 | 18 | 18 | 18 |

| Shut height | mm | 750 | 850 | 950 | 950 | 1100 |

| Rated tonnage point | mm | 6 | 6 | 6 | 6 | 6 |

| (L-R&F-B)Ram dimension | mm | 660*730 | 770*810 | 880*1050 | 1020*1080 | 1050*1130 |

| (L-R&F-B)Table simension | mm | 800*880 | 880*1000 | 1040*1080 | 1140*1140 | 1200*1200 |

| (L-R&F-B)Side window | mm | 550*550 | 600*600 | 700*700 | 1140*1140 | 1200*1200 |

| Main motor | Kw | 37kw*8p | 45kw*8p | 55kw*8p | 75kw*8p | 75kw*12p |

| Ram of adjustmant motor | Kw | 0.4w*4p | 0.75kw*4p | 0.75kw*4p | 1.5w*4p | 1.5w*4p |

| Motor of lubrication | Kw | 0.75w*4p | 0.75w*4p | 0.75w*4p | 0.75w*4p | 0.75w*4p |

| Ejector in the ram | Tons-mm | 6Ton-30mm | 10Ton-30mm | 10Ton-30mm | 10Ton-40mm | 10Ton-40mm |

| Ejector in the Table | Tons-mm | 8Ton-50mm | 12Ton-50mm | 12Ton-50mm | 12Ton-50mm | 17Ton-50mm |

| UP-Ejector hydraulic motor | Kw | 7.5kw | 7.5kw | 7.5kw | 7.5kw | 7.5kw |

| Down-Ejector hydraulic motor | Kw | 11kw | 11kw | 11kw | 11kw | 11kw |

| Working number-sidtance | NO | 1 | 1 | 1 | 1 | 3-200 |

| Air pressure | kg/cm2 | 5 | 5 | 5 | 5 | 5 |

| Press weight | kg | 50,000 | 65,000 | 90,000 | 105,000 | 140,000 |

| (L*W*H*)Press dimension | mm | 3425*3405*5280 | 3665*2655*5810 | 3690*3975*6150 | 4200*4200*6675 | 4410*4435*7800 |