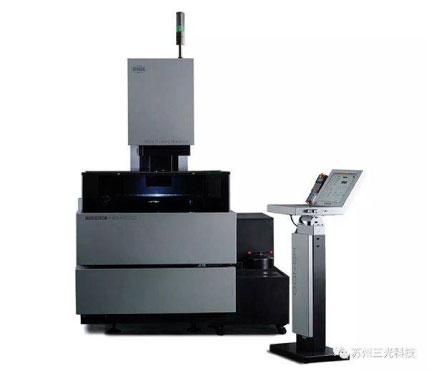

SSG

HB SERIES

Machine Features:

- มอเตอร์เชิงเส้นคือ "แม็กเลฟ" ในเครื่องมือกล เนื่องจากไม่มีการสัมผัสทางกล จึงมีการตอบสนองสูงและขจัดฟันเฟืองแบบบอลสกรู จึงสามารถรักษาความแม่นยำไว้ได้นานมาก

- เครื่องมือเครื่องตัดลวด HB400L ที่ขับเคลื่อนด้วยมอเตอร์เชิงเส้นตรง CNC แบบเต็มห้าแกน

- ไดรฟ์ลูปปิดเต็มรูปแบบของมอเตอร์เชิงเส้น (แกน X, Y)

- การควบคุมเชิงตัวเลขของแกน Z (การควบคุม CNC แบบเต็มแกน X, Y, U, V, Z ห้าแกน) เกิดขึ้นเป็นครั้งแรก

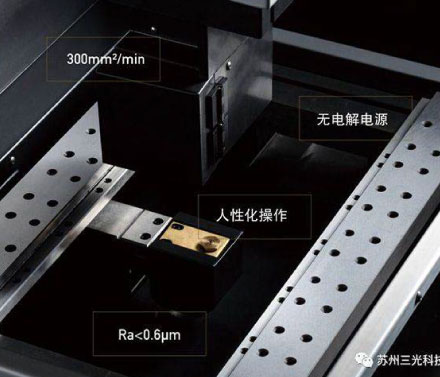

- เทคโนโลยีการจ่ายพลังงานแบบไม่ใช้ไฟฟ้าแบบเดิม

- ความหยาบสูงสุด: Ra0.6μm

- ความเร็วสูงสุดในการตัด 300㎜²/นาที

Machine Specifications:

| Model | HB400L | |

|---|---|---|

|

Machine body |

Worktable stroke(X,Y): 400*300mm |

400*300mm |

| Wire Speed | 1.18-11.8m/s | |

| Machine weight | 2260/2560㎏ | |

| Machine Dimension(L*W) | 2020*1700mm | |

| Max.workpiece height | 300mm | |

| Max. Cutting Angle | 20º/100mm | |

| Worktable size | 580*460mm | |

| Max.workpiece weight | 500㎏ | |

|

Water tank |

Filter accuracy | 0.01mm |

| Capacity | 130L | |

| Working Methode | FiltrationSystem | |

|

Pulse Power |

Max cutting speed | ≥300㎜²/min |

| Best Surface Finish | Ra≤0.6μm | |

| Max. Cutting Currrent | 12A | |

| CNC | Hardware Configurations: | |

|

Linear Motor, Full closed-loop |

||

| and Schneider Inverter | ||

| Data Port | USB, LAN | |

| Programming Code | ISO code | |

| Axis Numbers | ||

| 5-axis and 4 axis simultaneous control, | ||

|

pitch compensation realized |

||

|

Menu Language |

||

| Chinese/English/English (Inch)/ Italian/ Korean/JapaneseAluminum cutting option | ||

|

Power Supply |

Power | 380V±10% 50±1HZ |

| Working temperature | 10-35℃ | |

| Consumption | 1.2KVA | |

| Pneumatic Power | Air pressure | 0.5MPa above |

| Supply flow | 30NL/min(ANR) | |

| Air Port | 6(Innerdiameter) | |