4 ฟังก์ชั่นการใช้งานของเครื่องเลเซอร์

- Leapfrog

- Auto focus

- Automatic edge finding

- Micro-connection

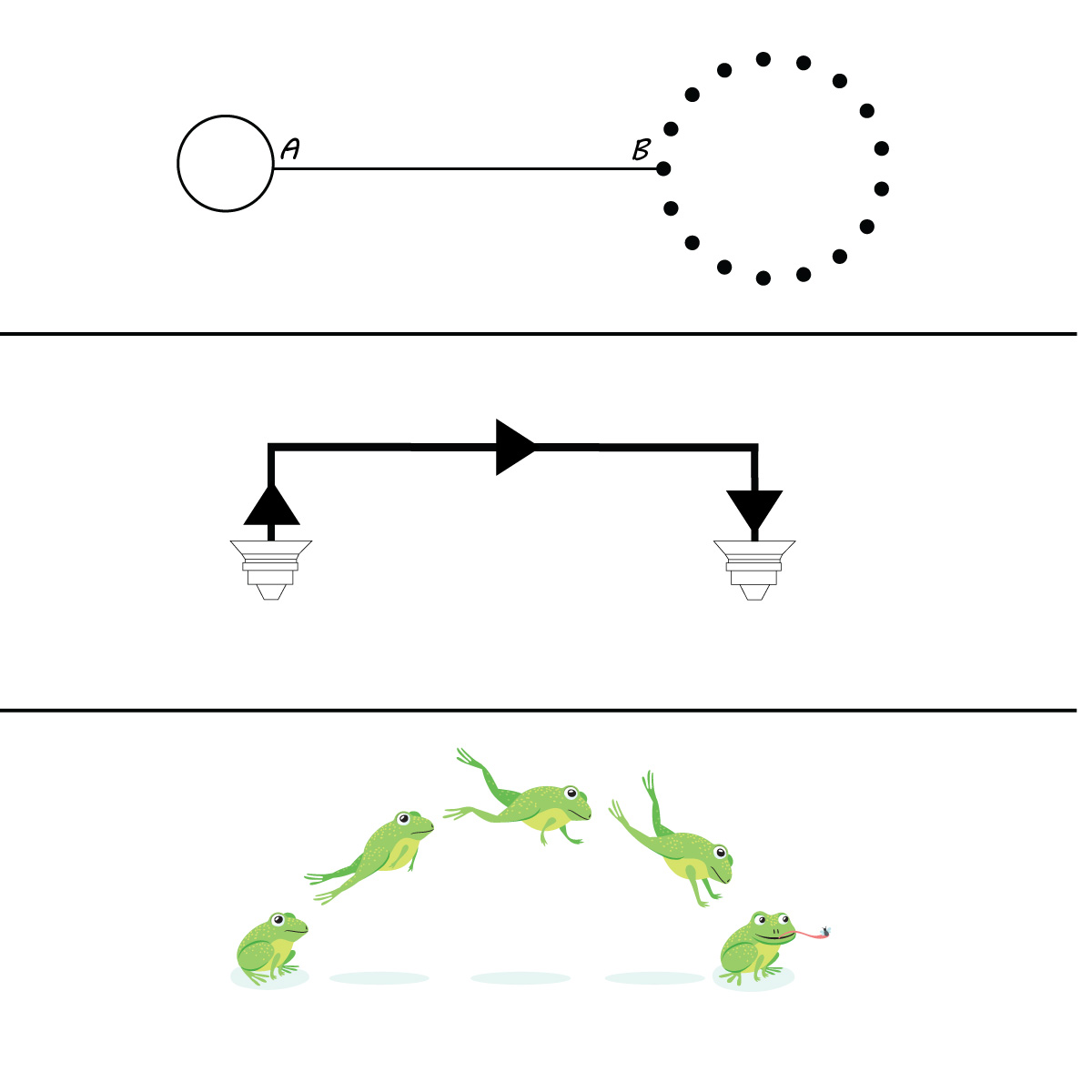

1. การกระโดด

Leapfrog เป็นการทำงานได้ดังรูป

หลังจากตัดรูที่ 1 แล้วรูที่ 2 ก็จะถูกตัด โดยหัวตัดจะเคลื่อนจากจุด A ไปยังจุด Bแน่นอนว่าแสงเลเซอร์จะปิดในระหว่างการเคลื่อนย้ายขั้นตอนการเคลื่อนที่จากจุด A ไป B โดยรันหัวตัดเลเซอร์แบบไม่ทำงาน

วิถีการเคลื่อนที่ของการวิ่งรอบเดินเบาของหัวตัดเป็นเหมือนส่วนโค้งที่กบกระโดดในกระบวนการพัฒนาเครื่องเลเซอร์ การกระโดดกบถือเป็นความก้าวหน้าทางเทคนิคที่โดดเด่นการกระทำกบกระโดด ใช้การเคลื่อนไหวแบนจากจุด A ไปยังจุด B เท่านั้น ขจัดเวลาในการขึ้นและลงสำหรับการกระโดดของเครื่องตัดเลเซอร์ ที่มีประสิทธิภาพสูงถ้าเครื่องตัดเลเซอร์ไม่มีฟังก์ชั่นการกระโดด ก็จะไม่ได้อยู่ในกระแสหลัก

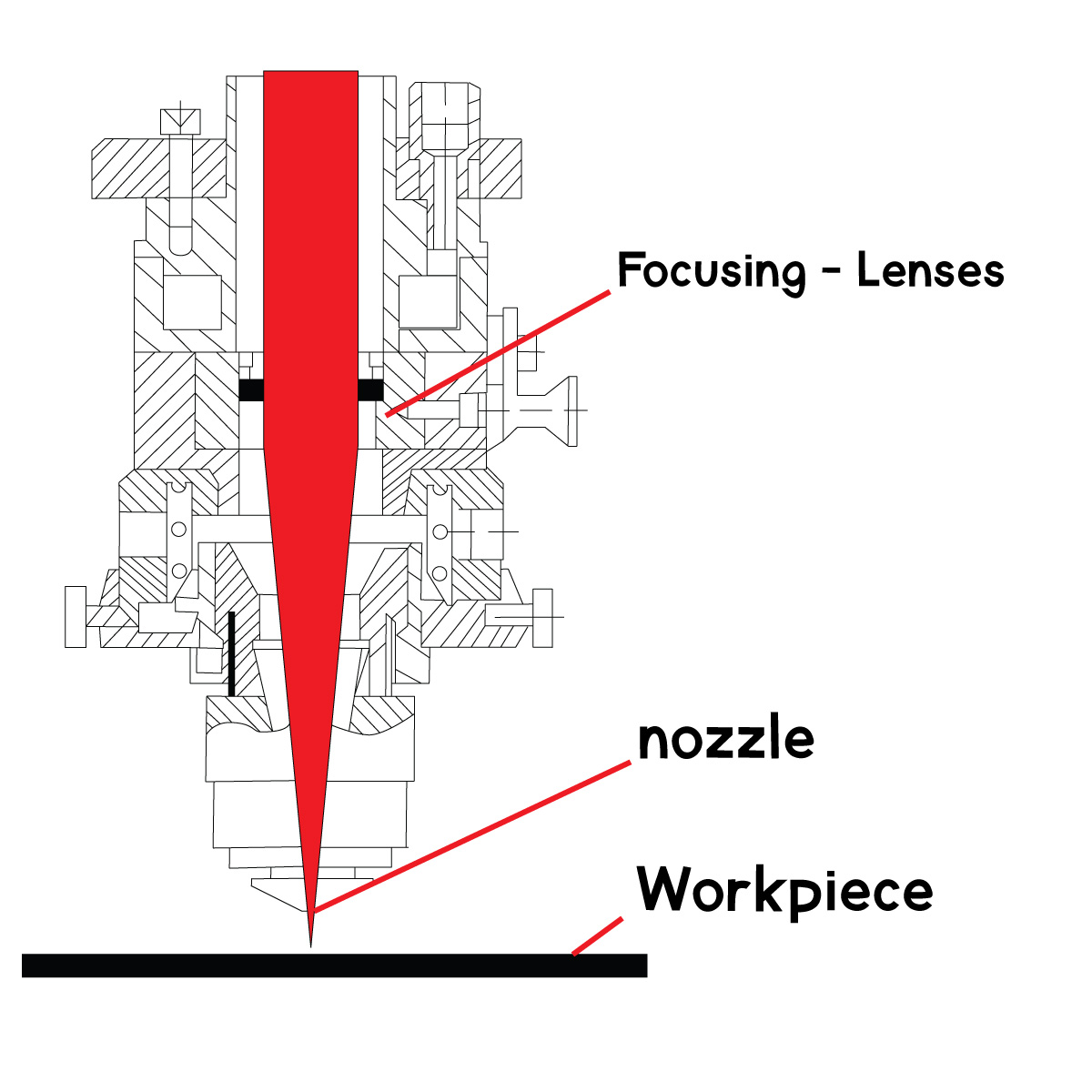

2. ออโต้โฟกัส

เมื่อตัดวัสดุต่างๆ จำเป็นต้องให้ลำแสงเลเซอร์โฟกัสไปที่ส่วนต่างๆ ของหน้าตัดของชิ้นงาน ดังนั้นจึงจำเป็นต้องปรับตำแหน่งของจุดโฟกัส(การปรับโฟกัส) เครื่องตัดเลเซอร์รุ่นก่อน ๆ มักเน้นแบบแมนนวล ปัจจุบันผู้ผลิตหลายรายมีเครื่องจักรที่มีระบบโฟกัสอัตโนมัติ ผู้คนอาจกล่าวกันว่าการเปลี่ยนความสูงของหัวตัดนั้นทำได้ เพียงยกหัวตัดขึ้น ตำแหน่งโฟกัสสูง หากหัวตัดต่ำลง ตำแหน่งโฟกัสจะต่ำ แต่มันไม่ง่ายอย่างนั้น

ในความเป็นจริง ในกระบวนการตัด ระยะห่างระหว่างหัวฉีดของชิ้นงาน (ความสูงของหัวฉีด) อยู่ที่ประมาณ 0.5- 1.5 มม. อาจถือได้ว่าเป็นค่าคงที่ นั่นคือ ความสูงของหัวฉีดยังคงไม่เปลี่ยนแปลง จึงสามารถยกและ ลดหัวตัดลงเพื่อปรับโฟกัส ความยาวโฟกัสของเลนส์โฟกัสไม่สามารถเปลี่ยนแปลงได้ ดังนั้นจึงไม่สามารถคาดหวังให้เปลี่ยนความยาวโฟกัสเพื่อปรับโฟกัสได้เช่นกัน หากตำแหน่งของเลนส์โฟกัสเปลี่ยนไป ตำแหน่งโฟกัสก็เปลี่ยนได้ หากเลนส์โฟกัสลดลง โฟกัสจะลดลง และหากเลนส์โฟกัสสูงขึ้น โฟกัสก็จะสูงขึ้น นี่เป็นวิธีหนึ่งในการปรับโฟกัสอย่างแท้จริง การใช้มอเตอร์เพื่อขับเคลื่อนเลนส์โฟกัสในการเคลื่อนที่ขึ้นและลงทำให้สามารถโฟกัสอัตโนมัติได้ วิธีการโฟกัสอัตโนมัติอีกวิธีหนึ่งคือ: ปรับความโค้งของตัวสะท้อนแสง (หรือเลนส์แบบปรับได้) ก่อนที่ลำแสงจะเข้าสู่เลนส์โฟกัส เมื่อเปลี่ยนความโค้งของแผ่นสะท้อนแสง มุมเบี่ยงเบนของลำแสงสะท้อนจะเปลี่ยนไป ส่งผลให้ตำแหน่งโฟกัสเปลี่ยนดังแสดงในรูปด้านล่าง ด้วยการโฟกัสอัตโนมัติ การประมวลผลของเครื่องตัดเลเซอร์สามารถปรับปรุงอย่างมีนัยสำคัญ เวลาในการเจาะแผ่นหนาลดลงอย่างมาก เครื่องสามารถปรับโฟกัสไปยังตำแหน่งที่เหมาะสมที่สุดโดยอัตโนมัติและรวดเร็วสำหรับชิ้นงานที่มีวัสดุและความหนาต่างกัน

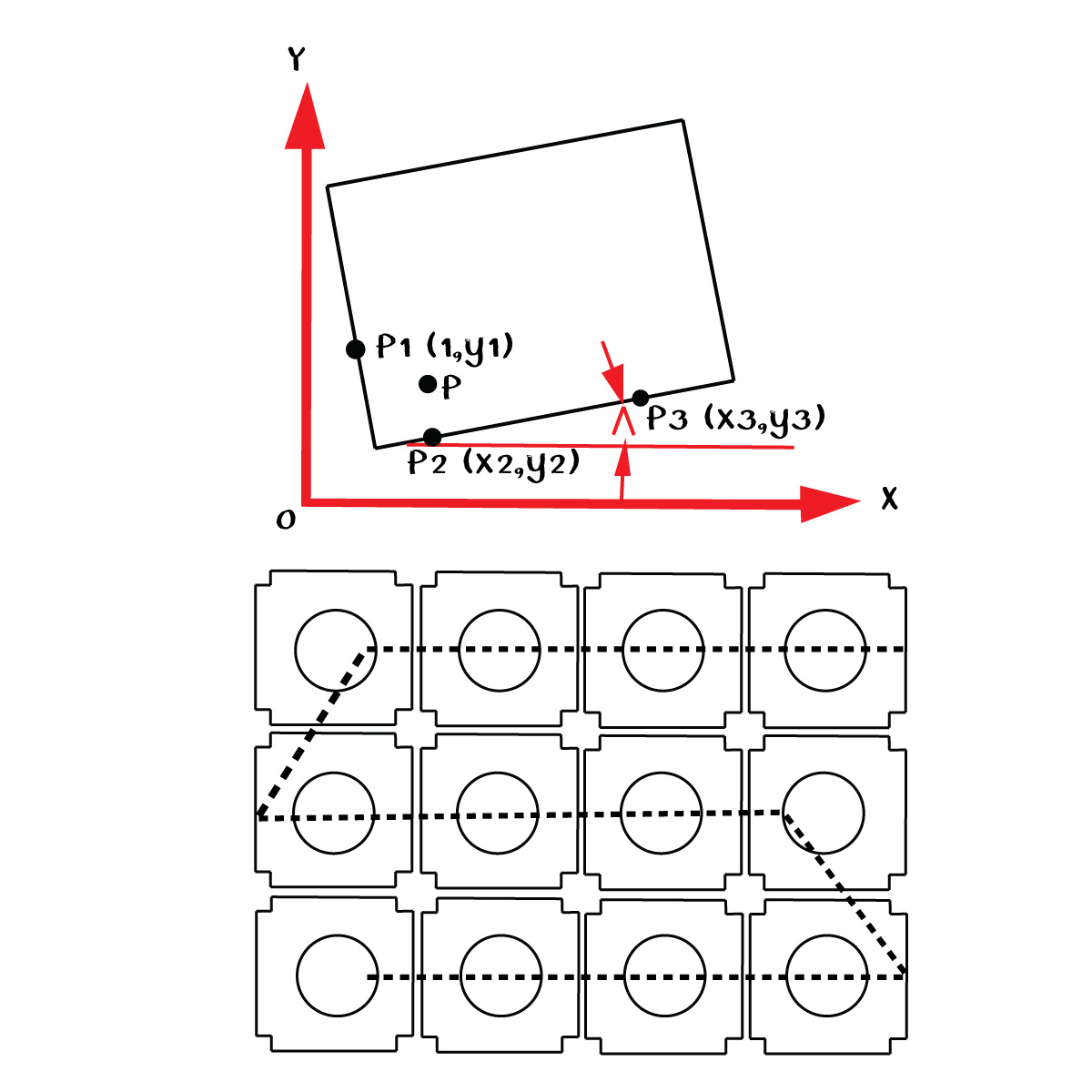

3. ค้นหาขอบอัตโนมัติ

ดังรูปด้านล่าง เมื่อวางแผ่นบนโต๊ะ หากเอียง อาจเกิดของเสียเมื่อตัด

หากสามารถตรวจจับมุมและจุดกำเนิดของความเอียงของแผ่นได้ในกระบวนการตัด สามารถปรับให้เข้ากับมุมและตำแหน่งของแผ่นได้ จึงหลีกเลี่ยงการสูญเสีย

ดังนั้น การค้นหาขอบอัตโนมัติจึงได้รับการพัฒนา เมื่อเปิดใช้งานฟังก์ชันขอบอัตโนมัติ หัวตัดจะเริ่มต้นจากจุด P และวัดสามจุดบนสองด้านแนวตั้งของแผ่นงานโดยอัตโนมัติ นั่นคือ P1, P2 และ P3 จากนั้นจะคำนวณมุมเอียง A และจุดกำเนิดโดยอัตโนมัติ. ฟังก์ชันค้นหามุมตัดอัตโนมัติ ประสิทธิภาพของเครื่องจักรจึงดีขึ้นโดยขจัดเวลาที่จำเป็นต้องปรับ (ย้าย) ชิ้นงานก่อนหน้านี้ ซึ่งไม่ใช่เรื่องง่ายบนโต๊ะตัดและมีน้ำหนักหลายร้อยกิโลกรัม เครื่องตัดเลเซอร์กำลังสูงที่มีเทคโนโลยีขั้นสูงและทรงพลังเป็นระบบที่ซับซ้อนซึ่งรวมเอาแสง เครื่องจักร และไฟฟ้าเข้าไว้ด้วยกัน ความละเอียดอ่อนมักถูกซ่อนไว้

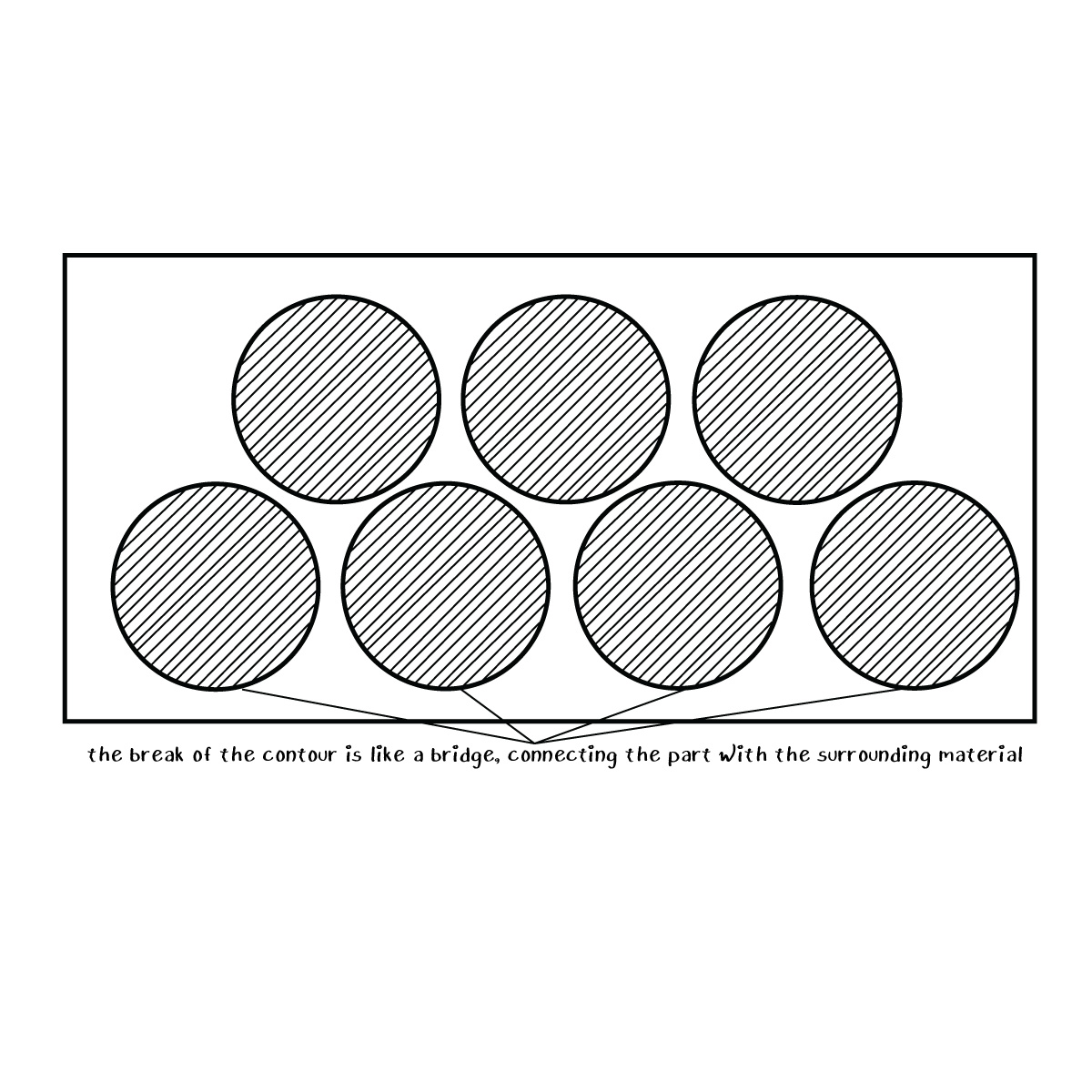

4. การเชื่อมต่อแบบไมโคร

ในระหว่างกระบวนการตัดด้วยเลเซอร์ แผ่นงานจะถูกยึดไว้โดยแถบรองรับฟันปลา หากชิ้นส่วนที่ตัดแล้วไม่เล็กพอ จะไม่สามารถหลุดออกจากช่องว่างของแถบรองรับได้ ถ้ามันไม่ใหญ่พอที่จะรองรับโดยแท่งรองรับ หรืออาจเสียการทรงตัวและวาร์ปได้ หัวตัดความเร็วสูงสามารถชนกับหัวตัดได้ ส่งผลให้เกิดการหยุดทำงานหรือสร้างความเสียหายให้กับหัวตัด สิ่งนี้สามารถหลีกเลี่ยงได้โดยกระบวนการตัดสะพาน (ข้อต่อขนาดเล็ก)

ชิ้นส่วนนั้นยึดติดกับวัสดุฐาน ดังนั้นจึงเรียกว่าตำแหน่งสะพานหรือการเชื่อมต่อแบบไมโคร บริดจ์เชื่อมต่อชิ้นส่วนกับวัสดุโดยรอบ และซอฟต์แวร์การเขียนโปรแกรมที่ซับซ้อนจะเพิ่มจำนวนบริดจ์ที่เหมาะสมโดยอัตโนมัติตามความยาวของโปรไฟล์ นอกจากนี้ยังสามารถแยกแยะระหว่างรูปทรงภายในและภายนอกและตัดสินใจว่าจะเพิ่มตำแหน่งเชื่อมหรือไม่ เพื่อให้รูปร่างภายใน(เศษ) ที่ไม่มีตำแหน่งเชื่อมหลุด ในขณะที่รูปทรงภายนอก(ชิ้นส่วน) ที่มีตำแหน่งเชื่อมยังคงติดอยู่กับวัสดุฐานและไม่ หลุดออกจึงไม่จำเป็นต้องคัดแยก

บริษัท สุทอง แมชชีนเนอรี่ จำกัด ดำเนินการธุรกิจนำเข้าและเป็นตัวแทนจำหน่ายเครื่องจักรอุตสาหกรรมงานโลหะ เครื่อง CNC และ Cobot (Collaborative Robot) ครบวงจร

- สามารถเข้าชมเครื่องจักรได้ที่โชว์รูม สุทอง แมชชีนเนอรี่

- เวลาเปิดทำการ : จันทร์-เสาร์ (8.00-17.00 น.) โทร 02-896-1818

- ติดตามข่าวสารได้ที่แฟนเพจ : Suthong1990