HEADMAN

High precision and high rigidity machining

Machine Features:

การกลึงงานที่มีความแม่นยำสูงและความแข็งแกร่งสูง

กลึง กัด เจาะ ต๊าปในเครื่องเดียว

1. จุดเด่นหลัก:

-

แกนหมุนไฟฟ้าขับตรง (Direct Drive Spindle): มีความแม่นยำสูง แข็งแรง ทนทานต่อการตัดหนัก (heavy cutting) และสามารถทำงานกลึงแทนการเจียรได้ (turning instead of grinding) มีการสั่นสะเทือนและเสียงรบกวนต่ำ ประหยัดพลังงาน และเกิดความร้อนน้อย

-

ป้อมมีดไฮดรอลิกเซอร์โว (Servo Hydraulic Turret): มีความแม่นยำและแข็งแรงสูง สามารถเปลี่ยนเครื่องมือได้อย่างรวดเร็ว (0.2 วินาที) และแม่นยำ รองรับแรงดันน้ำหล่อเย็นสูงถึง 7Mpa สามารถทำงานได้หลากหลาย เช่น กลึง กัด คว้าน เจาะ และต๊าปเกลียว

2. ระบบควบคุม CNC:

-

ใช้ระบบควบคุม SIEMENS 828D ซึ่งมีประสิทธิภาพยอดเยี่ยม

-

มีความแม่นยำในการคำนวณระดับนาโนเมตร (80-bit floating point nanometer calculation accuracy)

-

รองรับภาษาการเขียนโปรแกรม ISO และภาษาอื่นๆ

-

มีฟังก์ชันการจำลองการทำงาน (simulation) และรองรับแอนิเมชัน

-

มีฟังก์ชันการเขียนโปรแกรมอัจฉริยะ (Intelligent programming) ที่สามารถแปลงโมเดล CAD จากไฟล์ DXF ได้

-

ทนทานและไม่ต้องบำรุงรักษามาก (fan-less, hard disk-less design) ทำให้ทำงานได้อย่างน่าเชื่อถือในสภาพแวดล้อมที่สมบุกสมบัน

3. การใช้งาน:

-

เหมาะสำหรับงานกลึงที่มีความต้องการความแม่นยำสูงและผลิตภาพสูงในอุตสาหกรรมต่างๆ

โดยรวมแล้ว T55M Super Headman เป็นเครื่องกลึง CNC ที่ทันสมัย มีประสิทธิภาพสูง และได้รับการออกแบบมาเพื่อความแม่นยำ ความแข็งแรง และความน่าเชื่อถือในการผลิตชิ้นส่วน

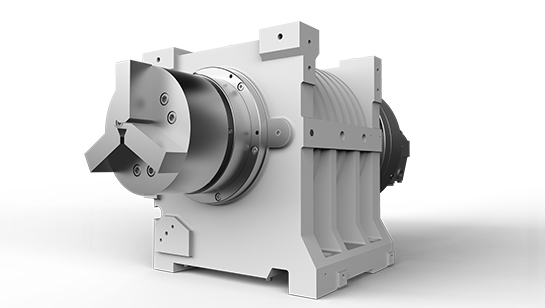

หัวจับมอเตอร์ในตัวแบบขับตรงด้วยเซอร์โวซิงโครนัสที่มีความแม่นยำและความแข็งแกร่งสูง

- ตลับลูกปืนด้านหน้าใช้ตลับลูกปืนเม็ดเรียวคู่แบบความแม่นยำสูงและตลับลูกปืนเม็ดกลมแบบแถวเดียวสัมผัสเชิงมุม ซึ่งสามารถรองรับแรงตามแนวแกนได้มากกว่า เพื่อให้สามารถตัดเฉือนหนักได้ และใช้ทดแทนการเจียระไน

- ความเร็วต่ำและแรงบิดสูง, ประสิทธิภาพการส่งออกสูง

- หัวจับขับเคลื่อนโดยตรงด้วยมอเตอร์ในตัว, ทำให้เกิด 'การส่งกำลังเป็นศูนย์' การออกแบบกะทัดรัด น้ำหนักเบา การสั่นสะเทือนต่ำ การผิดรูปจากความร้อนต่ำ พร้อมคุณสมบัติของแรงบิดสูงทั้งในความเร็วต่ำและความเร็วสูง มีความแม่นยำสูงทั้งในสภาวะไดนามิกและสถิต และมีความเสถียรสูง

- ความแม่นยำสูง, ความแข็งแกร่งสูง, ความเสถียรสูง, ประสิทธิภาพสูง

- การสั่นสะเทือนต่ำ, เสียงรบกวนต่ำ, มีความสมดุลดี, มีคุณสมบัติทางความร้อนที่ดี

Servo Hydraulic Turret & Live Turret

- ใช้โครงสร้างพื้นฐานที่มี การจัดทำดัชนีด้วยเซอร์โวมอเตอร์, การวางตำแหน่งด้วยฟันเฟืองโค้ง, และการล็อกด้วยระบบไฮดรอลิก

- ป้อมมีดหมุนเปลี่ยนตำแหน่งโดยไม่ต้องยกตัวขึ้น ช่วยลดการเคลื่อนที่ในการเปลี่ยนเครื่องมือ และป้องกันเศษวัสดุกับน้ำหล่อเย็นไม่ให้เข้าไปภายในป้อมมีด ซึ่งอาจส่งผลต่อความแม่นยำในการวางตำแหน่งได้

- จานฟันเฟืองถูกล็อกอย่างแน่นหนาด้วยแรงไฮดรอลิก เพื่อให้แน่ใจว่าน้ำหล่อเย็นแรงดันสูง 7 เมกะปาสคาลยังคงรักษาแรงตึงได้เพียงพอเมื่อไหลผ่านป้อมมีด

ระบบหัวจับอัตโนมัติ ความแม่นยำสูง พร้อมประสิทธิภาพระดับอุตสาหกรรม

เราออกแบบ Servo Hydraulic Turret เพื่อรองรับการผลิตที่ต้องการความแม่นยำและความรวดเร็ว โดยใช้โครงสร้างแบบเซอร์โวมอเตอร์ ร่วมกับเฟืองละเอียดและกระบอกไฮดรอลิก เพื่อให้สามารถเปลี่ยนทูลได้แม่นยำและมั่นคงในทุกสถานการณ์

จุดเด่นของระบบ Turret

-

ล็อกแน่นด้วยแรงสูง 2600 / 3600 / 6300 กิโลกรัม (ขึ้นกับรุ่น)

-

ความแม่นยำระดับสูง

-

แนวแกน X: ±0.001 มม.

-

แนวแกน Z: ±0.002 มม.

-

-

เปลี่ยนทูลรวดเร็วทันใจ

-

ความเร็วในการหมุน: 0.15 – 0.2 วินาที

-

รองรับหัวจับ 8 หรือ 12 ตำแหน่ง

-

-

ระบบ No Lifting

ไม่ต้องยกทูลตอนเปลี่ยน ลดเวลาและป้องกันการคลาดเคลื่อน

เหมาะสำหรับงานกลึงที่ต้องการความแม่นยำสูง และสามารถรองรับการผลิตทั้งแบบงานเล็กและงานอุตสาหกรรมขนาดใหญ่

CNC system

ประสิทธิภาพยอดเยี่ยม

SIEMENS 828D มีคุณสมบัติต่าง ๆ เช่น ความแม่นยำในการคำนวณระดับนาโนเมตรด้วยจุดทศนิยม 80 บิต, คอมไพเลอร์ภาษาโปรแกรม ISO และ ความเข้ากันได้กับภาษาโปรแกรมที่หลากหลาย, ฟังก์ชัน SMS, การจำลองการควบคุมเชิงตัวเลข (numerical control simulation), และ การรองรับภาพเคลื่อนไหว (animation support)

โปรแกรม CAD Reader เวอร์ชัน PC สามารถรองรับการแปลงแบบจำลองรูปทรง (Contour) และตำแหน่ง (location models) บนคอมพิวเตอร์ จากไฟล์รูปแบบ DXF ไปยังรูปแบบที่ระบบควบคุมสามารถจดจำได้ จากนั้น สามารถแก้ไขรูปทรงเหล่านี้ต่อได้ในโปรแกรม Contour Editor ในระบบควบคุม และด้วยความช่วยเหลือของ SinuTrain ทำให้สามารถตั้งโปรแกรมชิ้นงานบนคอมพิวเตอร์ได้เสมือนกำลังใช้งาน SIEMENS 828D บนเครื่องจักรจริง

ทนทานและไม่ต้องบำรุงรักษา

SIEMENS 828D ใช้แผงควบคุมด้านหน้าเป็น แมกนีเซียมหล่อขึ้นรูป ระบบ CNC ที่ออกแบบโดยรวมแผงควบคุมเข้ากับฐานเครื่อง (panel-base) ทำให้มี อินเทอร์เฟซน้อยลง รวมถึงมี ระดับการป้องกันสูง จึง ทำงานได้อย่างน่าเชื่อถือในสภาพแวดล้อมที่สมบุกสมบัน นอกจากนี้ SIEMENS 828D ไม่มีพัดลม ไม่มีฮาร์ดดิสก์ และใช้หน่วยความจำ NV-RAM ที่ไม่จำเป็นต้องมีแบตเตอรี่สำรอง ทำให้เป็น CNC ที่ ไม่ต้องบำรุงรักษาอย่างสมบูรณ์

ใช้งานง่าย

ระบบ SIEMENS 828D ใช้แป้นพิมพ์ CNC แบบเต็มรูปแบบพร้อมปุ่มกดระยะสั้น และจอแสดงผลสี TFT ความละเอียดสูงขนาด 10.4 นิ้ว / จอสัมผัสขนาด 15.6 นิ้ว ซึ่งใช้งานง่ายอย่างยิ่ง มีอินเทอร์เฟซ USB, CF card (สำหรับรุ่น 10.4 นิ้ว) และ RJ45 ที่ด้านหน้าแผงควบคุม ทำให้สามารถถ่ายโอนข้อมูล CNC ได้อย่างรวดเร็วและง่ายดาย

Machine Specifications:

| MODEL | T55M Super | ||

|---|---|---|---|

| Chuck aize | 8" | ||

| Max. swing diameter (mm) | ∅550 | ||

| Max. machining diameter(mm) | ∅300 | ||

| Max. machining length(mm) | 429 | ||

| Spindle bore(mm) | ∅62 | ||

| X axis travel(mm) | 195 | ||

| Y axis travel(mm) | 535 | ||

| Max. bar through diameter(mm) | ∅51 | ||

| Spinder nose | A2-6 | ||

| Spinder speed(r/min) | 5000(built-in motor) | ||

| Spinder motor power(continuous/30min)(kw) | 11/15 | ||

| Spindle axial runout (mm) | 0.003 | ||

| Spindel radial runout(mm) | 0.003 | ||

| No. of tool stations | 12 | ||

| Tool change time(s) | 0.2 | ||

| Turret locking type | hydraulic | ||

| Turret driven type | servo | ||

| Boring tool size(mm) | ∅40 | ||

| OD.tool size(mm) | □25 | ||

| Rapid feed speed X/Z (m/min) | 30/30 | ||

| Positoning accuracy X/Z (mm) | 0.008/0.008 | ||

| Repeatability positioning accuracy X/Z (mm) | 0.003/0.003 | ||

| Milling axis speed(r/min) | 5000 | ||

| Milling axis power(kW) | 3.77 | ||

| Milling axis capacity | Drilling : ∅16mm | ||

| End milling tool : ∅16mm | |||

| Face milling tool : M16 x 2 | |||

| Hydraulic station tank(L) | 20 | ||

| Hydraulic pump power(kW) | 1.5 | ||

| Nominal pressure (Mpa) | 3.5~6 | ||

| Lubrication tank (L) | 2 | ||

| Auto Lubrication pump power(W) | 25 | ||

| Coolant tank(L) | 130 | ||

| Coolant pump power(w) | 550 | ||

| Size (standard) | Length(mm) | 2560 | |

| Width (mm) | 1720 | ||

| Height (mm) | 1710 | ||

| Weight (standard)(kg) | 4000 | ||

| Voltage (3Phase)(V) | 380±10% | ||

| Frequency(Hz) | 50 | ||

| Tailstock type | servo | ||

| Tailstock quill diam(mm) | ∅70 | ||

| Tailstock travel + quill trave(mm) servo | 565 | ||

| Tailstack cone taper | M.T.4(dead type) | ||