As we said earlier that cost is an important factor in running a business When we invest, fast payback is the first issue we should consider.

What entrepreneurs need to know first of all, metal cutting is divided into 4 major types, which are

1.Plasma cutting

This type of cutting is a high energy cut. Makes it possible to cut the work with a greater thickness. But there will be a problem that the gap during work is very wide because of the high laser power. Causing the loss of more sheet meat than necessary Therefore, it is limited to shapes that cannot be cut very complicated. And most of them are cut work to be believed again.

2.Cutting with water pressure

Cutting with this system is a cutting that uses water, so it does not have high heat. It can cut a variety of work such as aluminum, steel, brass, copper, wood, plastic or even glass. Which cutting with water pressure is considered to be able to cut more precisely than plasma cutting. But it still has a wider cutting groove than laser cutting. And it is also a machine that requires high water pressure to cut the workpiece as well.

3.Laser cutting

This type of cutting is similar to plasma cutting. But it's different from the different light production processes. and thereby allowing the light energy of laser cutting to cut smoothly and Provides a very small groove to save sheet material. than plasma cutting and has very little discrepancy in the cut At present, the error is +-0.01, which is the cut that is considered the least inaccurate.

4.Cutting punching system

is the most different cutting method because it is a cut that is hammered down to cut the sheet using a beam like other machines. But this type of machine is limited by the shape, thickness and resolution that the machine can do. This type of machine will focus on the same work and a large number.

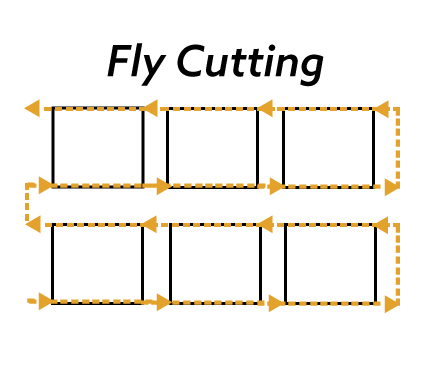

Butwe are going to talk about the cutting technology that comes with laser cutting (Laser cutting) is by using Fly cutting, which uses software to analyze the cutting. Makes the cut cut quickly by walking the cutting line in the same direction in a circle, making the laser cutting using this technology to save on the sheet and cutting time Makes laser cutting considered an investment that has been calculated as worthwhile that can be profitable for operators as quickly as possible.

สุทอง แมชชีนเนอรี่

ดำเนินการธุรกิจนำเข้าและเป็นตัวแทนจำหน่ายเครื่องจักรอุตสาหกรรมงานโลหะ

เครื่อง CNC และ Cobot (Collaborative Robot) ครบวงจร

● สามารถเข้าชมเครื่องจักรได้ที่โชว์รูม สุทอง แมชชีนเนอรี่

● เวลาเปิดทำการ : จันทร์-เสาร์ (8.00-17.00 น.) โทร 02-896-1818

● ติดตามข่าวสารได้ที่แฟนเพจ : https://www.facebook.com/suthong1990